Most Popular Products

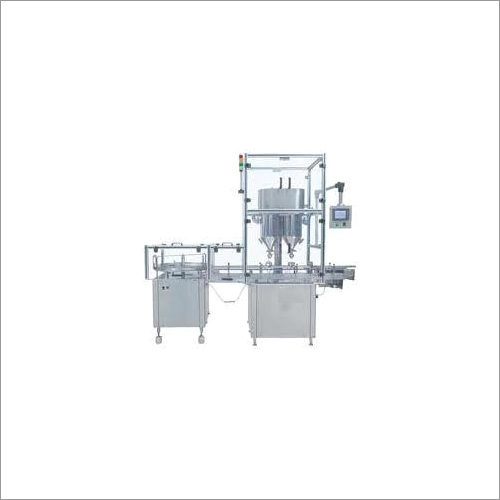

Screw Feeder Filling Machine

Price 270000.00 INR/ Piece

MOQ : 1 Piece

Screw Feeder Filling Machine Specification

- Product Type

- Screw Feeder Filling Machine

- Material

- Stainless Steel (SS304 Contact Parts)

- Application

- Powder Filling for Pharmaceuticals, Food, Chemical Industry

- Packaging Material

- Plastic, Glass, PET Containers, etc.

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic / Automatic

- Control System

- PLC Based Control

- Drive Type

- Electric Motor Driven

- Voltage

- 220V-240V AC

- Weight (kg)

- Approx. 120 kg

- Dimension (L*W*H)

- 800 x 600 x 1500 mm

- Capacity

- 20-50 Bottles/Min (Filling Speed dependent on product & bottle size)

- Feature

- High Precision Filling, Adjustable Speed, Anti-Drip Nozzle

- Color

- Silver / Metallic Finish

Screw Feeder Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Months

About Screw Feeder Filling Machine

We are amongst one of the foremost organization engaged in manufacturing and supplying, a huge range of Screw Feeder Filling Machine. The machine that we offer is designed by utilizing superior quality materials under the supervision of our professionals at our well equipped production unit. It is used for filling powders like chilli powder, spice powder, curry powder, talc powder, food powder, custard powder etc. in bottles, pouches, bags, containers or jars. Screw Feeder Filling Machine is widely tested on various parameters and is available in customization.

Advanced Filling Precision and Flexibility

Designed for accuracy, the Screw Feeder Filling Machine supports filling ranges from 10 g to 1000 g, making it suitable for both small and large production batches. Users benefit from high precision filling (1% accuracy) and customizable settings to accommodate various powder types and container sizes. The combination of single or optional double-head operation and adjustable speed enhances workflow efficiency and versatility.

Robust Construction and Safe Operation

Constructed with stainless steel (SS304 contact parts), the machine is built for durability and cleanliness. Safety features, including overload protection and an emergency stop function, safeguard operators and ensure trouble-free operation. The matt or mirror polish finish enhances both aesthetics and ease of maintenance, aligning with demanding hygiene standards in the food and pharmaceutical sectors.

Simple Control and Versatile Usage

This PLC-based electric filling machine offers intuitive control, supporting both foot pedal and fully automatic cycles. Its designed for a broad range of containers like bottles, jars, tins, and cans, compatible with packaging materials including plastic, glass, and PET. Applications span pharmaceutical, food, and chemical industries, optimizing productivity with computer-controlled precision and minimal human intervention.

FAQs of Screw Feeder Filling Machine:

Q: How does the Screw Feeder Filling Machine ensure high filling accuracy?

A: The machine utilizes a screw feeder mechanism driven by an electric motor and controlled via PLC, providing precise dosing with an accuracy of 1%. The system monitors product volume and nature to maintain optimal consistency during each filling cycle.Q: What types of containers can this machine accommodate for powder filling?

A: Designed for versatility, the machine handles bottles, jars, tins, and cans made from various materials such as plastic, glass, or PET. Adjustment options accommodate different container shapes and sizes within the specified filling range.Q: When is the foot pedal operation mode beneficial in this machine?

A: Foot pedal operation is ideal for semi-automatic production lines or when manual oversight is necessary for each fill. This mode improves control during batch processing or whenever precision handling is required for fragile or customized packaging.Q: Where is this screw feeder filling machine typically used?

A: This machine finds application in the pharmaceutical, food, and chemical industries. Its used for filling powders like medicines, spices, and chemical agents, especially where hygiene and accurate filling are critical.Q: What are the benefits of using a PLC-based control system in this filling machine?

A: PLC-based control enables precise fill management, adjustable parameters, and streamlined automation, leading to consistent output, simplified changeovers, and enhanced safety monitoring. This system also allows easy integration with other production equipment.Q: How does the anti-drip nozzle feature improve the filling process?

A: The anti-drip nozzle prevents spillage and ensures clean, accurate filling for each cycle. This reduces product wastage and keeps the workspace tidy, particularly when handling fine powders or sensitive ingredients.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Powder Filling Machine Category

Automatic Powder Filling Machine

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Product Type : Filling Machine

Drive Type : Electric

Servo Based Powder Filling Machine

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Computerized : Yes

Automatic Grade : SemiAutomatic

Product Type : Powder Filling Machine

Drive Type : Electric

Semi Automatic Powder Filling Machine

Price 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : SemiAutomatic

Product Type : Powder Filling Machine

Drive Type : Electric

|

MATRIX PACKAGING MACHINES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry